Getting Started with Mechanical Systems for Humanoid Robots

Getting Started with Mechanical Systems for Humanoid Robots

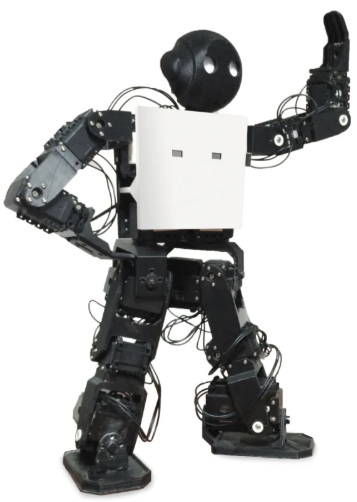

In this post, I share my journey as I started working on humanoid robots in 2014, focusing on mechanical systems and initial design considerations. For anyone starting in robotics, understanding the mechanical backbone of a humanoid robot is essential before diving into control algorithms or sensors.

Designing the Robot Structure

The structure of a humanoid robot is the foundation that supports actuators, sensors, and electronic components. A well-thought-out mechanical design ensures stability, reliability, and ease of maintenance.

Key considerations include:

- Material choice: Use lightweight yet rigid materials. Aluminum or high-quality plastics are common for prototypes.

- Joint placement: Proper spacing ensures that the robot can balance and move naturally without collisions.

- Ease of assembly: Modular designs help in quick assembly and replacement of faulty parts.

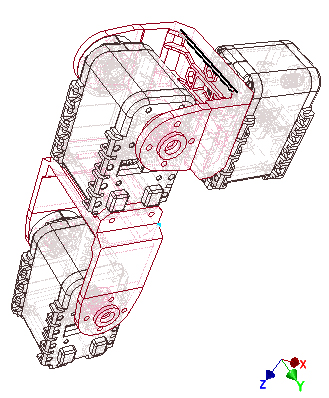

During my first project, I realized the importance of iterative design: initial ideas rarely work perfectly, so prototyping and testing each part is crucial. CAD tools like SolidWorks or Fusion 360 can help visualize assemblies and detect mechanical conflicts early.

Fabrication and Actuator Integration

Once the design is finalized, parts need to be fabricated. 3D printing is an excellent option for early prototypes because it allows rapid iteration and custom geometries.

- Custom brackets and joints: 3D printing lets you create parts that perfectly fit your robot’s unique structure.

- Strength vs. weight: Optimize infill and layer orientation to ensure parts are strong enough for the load.

- Surface finish: Smooth surfaces reduce friction in joints and improve the robot’s motion efficiency.

Servo motors are the backbone of actuation in humanoid robots. Choosing the right servo is critical:

- Torque and speed: Match the torque to the weight of the limb and the desired speed of motion.

- Voltage and control: Ensure compatibility with your electronics and control interface.

- Reliability: High-quality servos last longer and provide more consistent motion, especially under continuous use.

During my project, integrating the servos into the mechanical frame required careful alignment and calibration. Even a slight misalignment can introduce unnecessary stress and affect motion smoothness.

Kinematics and Early Testing

Before moving on to software control, I performed basic kinematic tests:

- Checking if joints moved freely within expected ranges.

- Ensuring that limbs did not collide during simple motions.

- Measuring weight distribution and balance to prevent tipping.

These tests are crucial in avoiding mechanical failures later when programming walking or manipulation behaviors.

Lessons Learned

Working on mechanical systems for humanoid robots taught me several important lessons:

- Iterate quickly, fail safely: Early failures provide valuable feedback.

- Plan for assembly: Designing modular parts saves time during repairs and upgrades.

- Integrate electronics thoughtfully: Space for wires, sensors, and controllers should be planned from the beginning.

- Test incrementally: Don’t wait for full assembly to test; test subassemblies to catch issues early.

By paying attention to these details, a humanoid robot project becomes manageable, educational, and much more likely to succeed.

Conclusion

Starting with mechanical systems lays a solid foundation for all future robot development. Focusing on structure, fabrication, and actuation ensures that the robot can support advanced behaviors later. Iterative design, careful servo selection, and incremental testing are key steps in building a reliable humanoid robot.